diy injection molding press

The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity. Remove all the burrs.

Bench Model Plastic Injection Machine

Of course there are a number of DIY injection molding projects to choose from but they usually involve a fair amount of tools and labour.

. C Clamp the mold in place by turning the vise handle clockwise. Bolzbrain wanted to bypass all of the heavy cutting welding and frame assembly work so hes built himself a DIY Injection Molding Press for cheap using an off the shelf six ton hydraulic press. Inexpensive homemade molds can be made using an epoxy or urethane resin.

Plastic-made pellets of your choice. Well use the open-source Blender but the workflow should be fairly similar in any other CAD software. DIY Injection Molding Step by Step 1.

To keep things this way we finance it through. The video series covers the complete build fro. A benchtop injection molder such as the Galomb Model-B100 or the Holipress.

Design the Mold in CAD First pick the CAD software tool of your preference to design the mold insert. Bolzbrain wanted to bypass all of the heavy cutting welding and frame assembly work so hes built. I did injection molding for a living years back never had a blowout on a 75 ton press never lost a finger nor a serious injury where pressures far exceed with risks than a.

Download the blank mold insert design files youll use them to create your injection mold design. Small Injection Molding Machine from Galomb. As luck would have it you can get a nice-looking pneumatic press for less than 350 and with a little more money spent Kurt found he could convert it into a functional injection molding.

Be sure to check out the newest version of the machine called the MK3 herehttpsyoutubehw4NI60WW8IThis video will show you how to build your own. DIY Injection Molding Step by Step 1. The molten plastic then gets injected into your mold cavity through the machines injector.

Pull it back out and take the band heaters. Step 7 Inject the plastic and let it harden Once you have set up your injection molding machine pour in your plastic pellets. We designed and developed a homebuilt full.

Download the blank mold insert design files youll use them to create your injection mold design. It sure looks a lot more robust than the typical benchtop injection molding machines I had been seeing. Plastic pellets of multiple colors are available in the market off-the-shelf.

To design the mold insert use a CAD software tool of your choice. DIY desktop injection molding is finally a reality. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle.

After building our DIY homemade CNC milling machine from scratch we wanted to push our home shop to the limits. Professional injection molding in small quantities can be quite expensive and buying a manual machine can cost quite a bit. A brand new machine like the Galomb is circa 1500-1800.

Design the Mold in CAD First pick the CAD software tool of your preference to design the mold insert. Shove the steel axis into the steel pipe if it does not fit use the turning table to reach the right diameter. You wont need a machine shop at home and you can even build the mold itself using a DIY CNC machine.

You can choose whatever color you want. We built an extremely small and easy-to-use desktop size plastic injection machine and were calling it. Of course there are a number of DIY injection molding projects to choose from but they usually involve a fair amount of tools and labour.

These injection molding machines are perfect for use at home. PART-1 DIY video of how to design and build a small miniature pneumatic air actuated desktop molding machine. Instructions for building one also are on the Action Box channel.

A 3D printing material that can survive the heat and pressure applied to the mold during injection molding. Read on to see the best DIY and desktop injection molding machines. Benchtop Injection molders come in a variety of price ranges.

Professional small-batch injection molding can be pretty expensive and buying a manual machine can cost quite a bit. Drill a hole with a 20mm drill in the side of the pipe 500mm from the bottom. A Place a mold in the machine.

Of course there are a number of While 3D printing is now easily accessible and inexpensive there are still some use cases where you need the benefits of injection molding for small batches as well. These machines are designed to make it easy to prototype injection molded parts test molds and even do small production runs. Printables Basics Buyers Guides Reviews Deals.

Well use the open-source Blender but the workflow should be fairly similar in any other CAD software. Professional injection molding in. Get It 3D Printed This article is free for you and free from outside influence.

Tabletop Injection Molding Machine Still A Big Hit

How To Do Injection Molding Diy

Quick Release Toggle Mold Clamp

Diy Injection Molding Plastic Injection Molding Injection Moulding Plastic Injection

Model 150a Plastic Injection Machine Injection Machine Plastic Injection Diy Cnc Router

Plastic Injection Moulding Machine Model 4

Lns Technologies Plastic Injection Molding Machines And Supplies Photos

Desktop Injection Molding Machine Get Inquiries 56

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

Up For Sale Is A New Unused Powerlab Model 330 1 3 Ounce Benchtop Injection Molding Machine Perfect Fo Plastic Moulding Plastic Injection Molding Diy Molding

Homemade Plastic Injection Molding Machine

Build Make Plastic Injection Molding Drill Press Attachment Diy How To

Make Your Own Injection Molding Machine

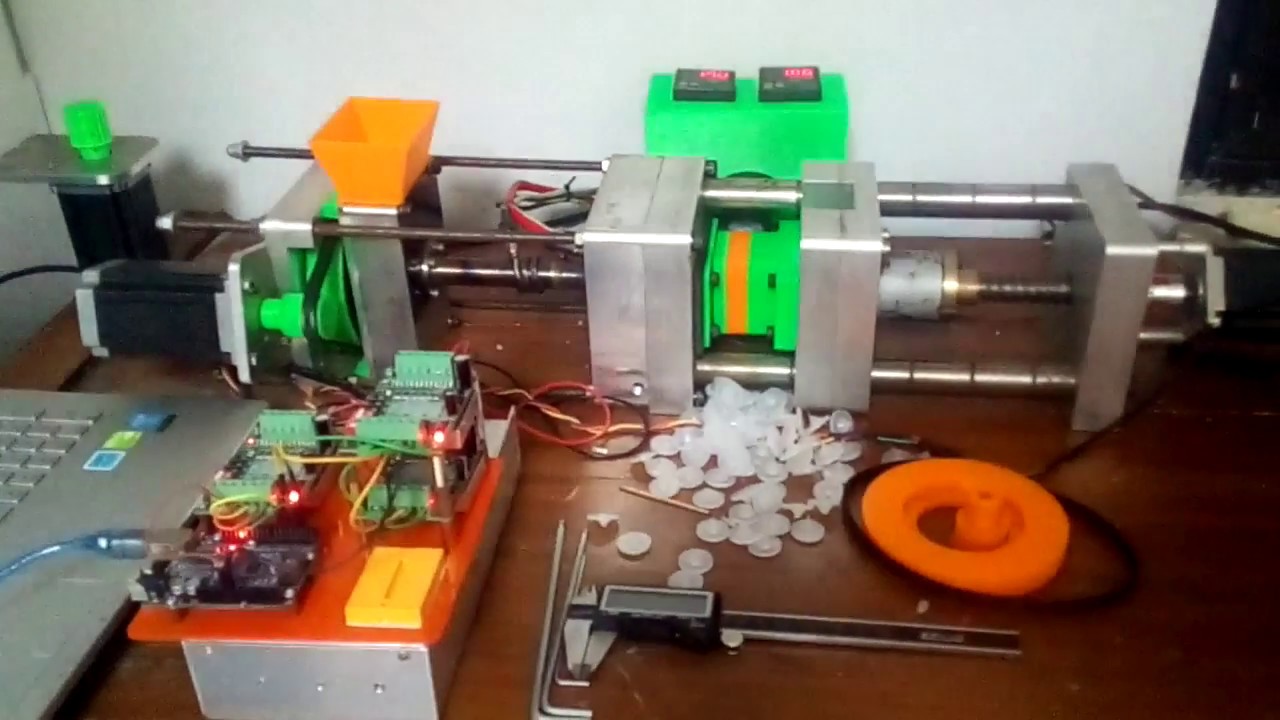

Desktop Injection Support By 3d Printed Controlled By Arduino Uno

Throwback Thursday The Remington Nylon 66

Plastic Injection Molding Glossary Plastic Injection Molding